What We Can Do

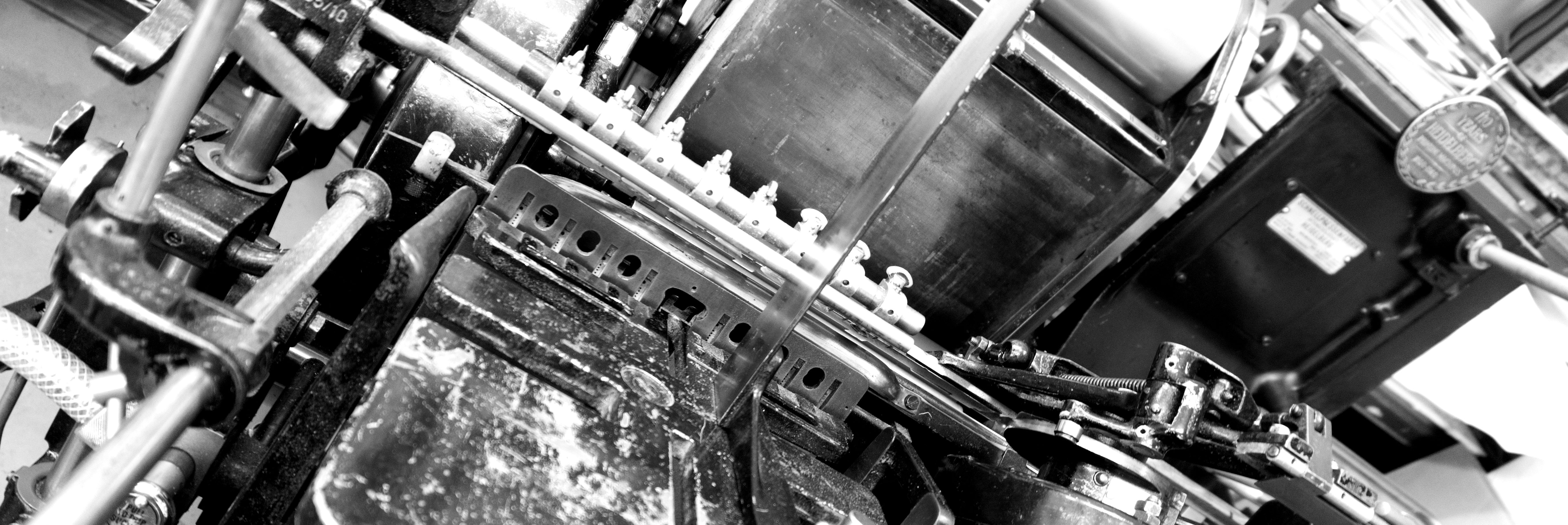

Letterpress Printing

We are letterpress printers and have been printing letterpress for nearly 25 years.

We have a large selection of letterpress printing presses which are used on a daily basis and can print from tiny stamp sizes to large format posters.

If you have a project that you would like to talkto us about please feel free to get in touch, drop us a line at info@letterpressdesign.co.uk

Current Presses and Capability

2 x Heidelberg Platens 10 x 15

1x Heidelberg Platen 10×15 – Hot Foil

1 x Heidelberg Platen 13 x 18

1 x Chandler and Price Treadle Press Crown Folio

1 x Jardine Treadle Press 9×6 chase

1 x Farley CWP 25 Flat Bed Proofing Press

2 x Marshall DUT hand Foilers

3 x Adana 8×5 – normally used for workshops

1 x Adana 6×4

1 x Adana 5×3

1 x Adana Quarto QH

1 x 520 Ideal guillotine

1 x Paper Drill

1 x Universal Corner rounder

1 x 600×300 Kent Laser

A large selection of Wood and Metal types as well as the use of photopolymer plates.

Hot Foil Printing

We are fortunate to have the capablilty to use hot foil to enhance our printing or just use purely on it’s own. Hot Foil printing can  give a similar impression to a deep letterpress impression but with the added bonus of some shine.

give a similar impression to a deep letterpress impression but with the added bonus of some shine.

For the smaller work we use our marshall table top foilers but when we need something bigger or for large runs we use our Heidelberg Platen.

Hot foil uses magnesium or brass plates which are heated to high temperatures, when used with a special foil we get a lovely shiny finish to our work.

Thermograhpy

Thermography is another process that work really well with letterpress. Whether it is applied to the entire print or to just certain parts it can enhance a design.

Thermography is another process that work really well with letterpress. Whether it is applied to the entire print or to just certain parts it can enhance a design.

After we have finished printing letterpress a fine powder is applied to the wet ink, this is then passed through a heat source which raises the powder and gives an engraved finish.

When we are using thermo powders we normally make sure that the print has as little impression as possible so that the raised thermo powders look as effective as they possibly can.

Thermography powders come in lots of colours but we can also use a clear gloss or satin if you have a particular colour in mind.

Bronzing

‘Bronzing’ is another process that works really well with letterpress printing and is often used in pplace of hot foil. It can be more cost effective on smaller runs and give a more subtle finish to the print than you would normally get with hot foil.

‘Bronzing’ is another process that works really well with letterpress printing and is often used in pplace of hot foil. It can be more cost effective on smaller runs and give a more subtle finish to the print than you would normally get with hot foil.

A fine metallic ‘bronzing’ powder is applied to the wet ink, this is then allowed to dry before being dusted off again.

There are 3 main bronzing colours, gold, silver and a copper but other perlescent finished are also available.

Embossing

Normally when we print letterpress, the design is printed just on to the card, a kiss impression (old school) or more recently we give more impression to the design to get a more tactile finish, this is called the deboss, the design goes in to the card.

Normally when we print letterpress, the design is printed just on to the card, a kiss impression (old school) or more recently we give more impression to the design to get a more tactile finish, this is called the deboss, the design goes in to the card.

The opposite of this is an emboss, where the design itself is raised. We can blind emboss using all of our letterpress machines, this means that we cannot use ink, but if you would like some colour we can use one of the hot foil presses to achieve this result.

Die Cutting

Die-cutting has it’s place with packaging but we often use it to create wraps for invitations and for finishing greetings cards to name but a few.

An additional cutting forme is made and placed in the press, once we have completed our printing the work gets one axtra run through the press to cut it to shape.

The pictures demonstrate the recyclable packaging that we produced for Wingback products. After printing the design letterpress that are then fed through the larger Heidelberg 18×13 to be cut and creased.

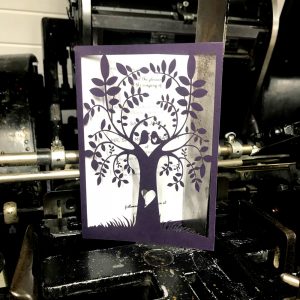

Laser Cutting

Laser cutting is not something we do a lot of but is something that we can do. We prefer working on darker colours so that you can’t see any marks from the laser. The actual cutting of a design doesn’t take a lot of time but getting the design sorted does, so if you’re after something bespoke please be aware of the time and cost implication for this.